-

Metalo apdirbimo

-

Tekstilės

-

Maisto

-

Baldų

-

Plastiko

-

Spaustuvių

-

Energetikos alyvos

-

Elektrinės

-

Chemijos

-

Geležinkelių

-

Dujų

-

Naftos

-

Laivybos

-

Elektronikos

-

Trikotažo mezgimo

-

Cemento

-

Popieriaus

-

Farmacijos

-

Stiklo

-

Vandentvarkos tepalai

-

Konstruktyvo

-

Statyba

-

Žemės ūkis

-

Kelių tiesimo

-

Gręžiniai, gavyba

-

Medienos

-

Pakuotės

-

Grūdų perdirbimo

-

Kuro

-

Metalų apdirbimo

-

Guoliams

-

Įvorėms

-

Grandinėms

-

Pavaroms

-

Dantračiams

-

Trosams

-

Sriegiams

-

Kreipiančiosioms

-

Elektros varikliams

-

Movoms

-

Konvejeriams

-

Prietaisams

-

Turbinoms

-

Transformatoriams

-

Staklėms

-

Hidraulikai

-

Pneumo sistemai

-

Šaldytuvams

-

Oro kompresoriams

-

Vakuuminiams siurbliams

-

Šilumokaičiams

-

Suvirimo aparatams

-

Formoms

-

Klojiniams

-

Metalo apdirbimui

-

Linijiniams kreipikliams

-

Pjūklams

-

Vandens siurbliams

-

Gofruotuvams

-

Granuliatoriams

-

Plastikui

-

Vožtuvams

-

Robotams

-

Centrifugoms

-

Laboratorinė įranga

-

Difuziniai siurbliai

-

Sklendėms

-

Siurbliams

-

Orapūtėms

-

Tekstilės adatoms

-

Sandarinimo žiedai

-

Deguonies įrangai

-

Kabelių pratraukimui

-

Gumai

-

Spyruoklėms

-

Centrinės tepimo sistemos

-

Mezgimo mašinoms

-

Platinoms ir kabliukams

-

Verptuvams

-

Žarniniams siurbliams

-

Staklių sūkliams

-

Juostiniams pjūklams

-

Galandimui

-

CNC tepalai

-

Elektros kontaktams

-

Tarpinėms

-

Aliuminiui

Aliuminiui

© 2021 UAB "Mechanica"

© 2021 UAB "Mechanica"

- Tepimo sprendimai pramonei

- Dujų

- Turbininių dujų skaitiklių alyva

Turbininių dujų skaitiklių alyva

Turbininių dujų skaitiklių alyva

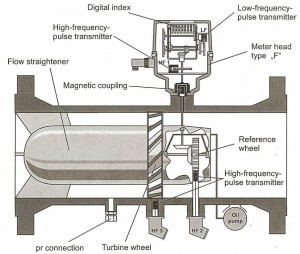

Turbininiai dujų skaitikliai yra išvadinio tipo dujų skaitikliai, kurie naudoja dujų greitį, kad nustatytų per skaitiklį praeinančių dujų tūrį. Tomas rodomas tiesioginio skaitymo skaitiklio tipo rodyklėje. Turbininiai dujų skaitikliai puikiai tinka aptarnavimui, kur svarbus dujų tiekimo tęstinumas, nes jie gali praleisti dujų srautą, kai nutrūksta skaitiklio aptarnavimas.

Dujų apskaitos turbininio skaitiklio tepalas

Turbininis dujų skaitiklis puikiai tinka antriniam matavimui pramonėje, kur dujų srauto tęstinumas yra labai svarbus. Naudodami dujų greitį dujų tūriui skaitiklyje matuoti, šie išvadiniai skaitikliai matuoja srautą pagal skaitiklio parametrus.

|

Rūšis |

Klampumas prie 40ºC, mm2 /s |

Tankis, prie 15ºC, kg/m3 |

Pliūpsnio temperatūra PMCC, ºC |

Stingimo temperatūra ºC, |

Panaudojimas, savybės |

|

Molyduval Herkules SE 15 |

15 |

910 |

224 |

-63 |

Pilnai sintetinė, tausojanti aplinką, biologiškai iri turbininių matuoklių alyva(CEC L-33-T82, 90 %), naudojama kaip alternatyva aviacinėms alyvoms. Plataus temperatūrinio diapazono ir ypač tinkama lauke instaliuotiems matuokliams žiemos lauko sąlygoms. Atitinka

reikalavimus. Pakuotė : 5 LTR bakeliai |

Keičia seną naudotą aviacinę Aeroshell Fluid

Turbininio dujų skaitiklio alyva

Turbininiai skaitikliai susideda iš sandaraus korpuso, ekstruzijos sekcijos, turbinos rato ir krumpliaračio sistemos, kuri vadovauja skaitiklio indeksui.

Dujų srauto metu sukasi turbinos ratas. Turbininis matuoklis pagamintas taip, kad turbinos rato sukimosi dažnis būtų proporcingas srauto greičiui. Tokiu būdu dujų tūris apskaičiuojamas pagal turbinos rato sukimąsi.

Nukrypimai nuo paklaidos kreivės daugiausia atsiranda dėl mechaninių nuostolių, atsirandančių dėl trinties prie guolių ir krumpliaračio sistemos. Turbininiai skaitikliai dažniausiai įrengiami ten, kur reikia išmatuoti didelius dujų kiekius, vidutinio ir aukšto slėgio stotyse. Šiuose skaitikliuose yra vienas ar daugiau impulsų generatorių, kurie gali tiekti aukšto arba žemo dažnio impulsus.

Turbininiai matuokliai, kaip ir kiti srauto matuokliai, yra jautrūs sutrikdytam srauto profiliui prieš srovę.

Use and Calibration of gas meters

Nowadays, that all the physical quantities’ measurements are part of the production process as well as the billing process, it is very important to be precise and reliable.

Gas meters are no exception. During their usage period, gas meters must be in good operational condition and must have a valid calibration certificate. Proper operational condition depends on the correct use and maintenance. Nevertheless, in order for a gas meter calibration to be valid, the following criteria must be fulfilled:

The calibration conditions must be equivalent to the gas meter’s installation conditions.

It is recommended that the gas meters should be calibrated under conditions as close as possible to the ones during the meter’s actual operation. Special attention must be given to the calibration medium (natural gas or atmospheric air), the pressure, the temperature and the upstream and downstream piping.

If possible, the required adjustments must be performed in order to have a predictable and reliable operation of the gas meter.

All gas meters require periodic calibration even though some commercial literature claims the opposite. Non-regularly calibrated gas meters, may produce significant errors.

Calibration must be performed by accredited and traceable laboratories.

When the laboratory performing the calibration, is accredited according to ISO/IEC 17025:2005, the following parameters are guaranteed:

The reliability of the measurement results and the calibration certificates.

The appropriate environmental conditions and laboratory facilities, during the calibration.

The accuracy of the reference equipment used for the calibration.

The validity of the calibration procedures and the measurement uncertainties calculation.

The measurements’ traceability to national standards.

The laboratory’s participation in Interlaboratory Comparisons.

The Best Measurement Capabilities, which are the lowest measurement uncertainties that the laboratory can achieve within its scope of accreditation.

The gas meter’s calibration must be valid during its period of operation.

In order to fulfill this requirement, the following question must be answered:

How often do we calibrate a gas meter?

This is a question that often arises. The answer to this question is not easy. All gas meters must be regularly calibrated, regardless of their type, size, construction or age. But how often?

Time has significant influence on the gas meter’s performance. As time passes, gas meters tend to drift due to gradual and sometimes imperceptible environmental effects. Variations may exist even if there is no obvious damage to their internal parts. This is why recalibration is necessary.

The most common practice is to define a short recalibration period for the new gas meters and the meters used in new applications or environments. Afterwards, as sequential calibrations are performed, the drift between each calibration can be evaluated. Based on these data, the user can decide whether to increase or decrease the recalibration interval.

The calibration laboratory can help its customers determine the appropriate calibration intervals. The gas meter’s calibration history can be studied by the laboratory and an evaluation of the drift can be performed, in order to define the suitable recalibration interval.

Factors affecting the performance of a gas meter

The most important factors that affect the performance of a gas meter are:

Deposits on internal surfaces. Layers of salt, minerals, oxidation etc. can have measurable affects on a gas meter’s performance, even if it seems to operate correctly. All types of gas meters can be affected, even the ones without moving parts like Coriolis, Vortex, Ultrasonic, etc.

Chemical attack, influences gas meters, especially those having moving parts. A change to the geometry of a turbine meter for example, will affect its performance.

Abuse (shock, over speeding etc.) even when there is not any obvious damage, can cause variation of the gas meter’s performance characteristics.

Aging of gas meters causes changes (sometimes even improvements) on their performance.

Electrical changes usually occur as a result of aging.

Mechanical changes to meter performance due to the bearings usually occur soon after the manufacture of the meters or the bearings replacement and continue with a much slower rate during the lifetime of the gas meter.

Fluid property differences are a very important factor. If a gas meter has been calibrated in one type of fluid and used in another, significant differences may be observed.

Improper installation is another major factor affecting the differences between the calibration results and the actual operation of the gas meter.

External influences affect all types of gas meters. Some meters are affected from vibration, others from temperature or pressure.

The conclusion resulting from the aforementioned is that gas meters, depending on their type and their operation conditions, must be calibrated within appropriate time intervals and from a suitable calibration laboratory, in order to provide reliable results. Don’t forget that gas meters are mainly used for billing purposes.

Copyright : Written by Sofia