PFPE grease - A Unique Lubricant for a Unique Application

General Properties

PFPE greases are homogenous, white, thick and particularly resistance to oxidation and to chemical agents. Further, they are compatible with all types of material (glass, metals, elastomers, plastics, ceramics) and their properties remain unaltered over wide temperature ranges. PFPE greases can be used in the presence of water, oils, vapor and, in general, with all organic substances and solvents which are not highly fluorinated, without being removed, dissolved or modified in any way.

- Our PTFE synthetic, fully fluorinated grease offer excellent high temperature and load bearing characteristics. They are also resistant to chemical agents, acids and alkali as well as water and vapours. They are often used in the lubrication of bearings on furnace trolley wheels and mechanisms in contact with oxygen, alkalis, solvents, gas and flammable fuels. They have an extremely long life and excel in aggressive working conditions.

- Synthetic fully fluorinated materials are used as lubricants and coatings in the most extreme & critical lubrication applications. Fluorinated oils and greases offer the ultimate in lubricant performance throughout a wide range of different industries and applications where conventional and other synthetic lubricants are not able to survive.

- IKV fluorinated lubricants are marketed under the brands ZAROX and FLUOR offer the ultimate in choice from a full range of different viscosity fluids, pastes, greases and dispersions with additives where required to suit the specific application. They are also available in a range of different fluid and grease based aerosols.

Lubricating greases based on perfluorinated polyether (PFPE) have been predestined for a long time as niche products, providing long-life lubrication at temperatures above 200°C, in aggressive chemical environments, in vacuum devices or as an inert media to lubricate and/or protect sensitive materials like plastics and elastomers.

This group of specialty greases is now becoming also competitive in a range of applications where less expensive and less-performing lubricants are normally used. Modern PFPE greases can offer both performance advantages and a lower total cost of ownership (purchase price + the costs of operation). The lubrication of different devices in traditional and electric cars has proved to be one of the successful uses of PFPE greases. This paper will overview and discuss the new possibilities in the development and application of PFPE greases.

PFPE Grease

Our PFPE greases are based upon fluorinated fluids thickened with PTFE to make a wide range of different greases. They offer excellent high and low temperature performance, excellent load bearing characteristics and are chemically resistant for use in critical applications within a diverse range of industries.

They are resistant to chemicals, acids and alkalis, water, steam and gases. They are often used in the lubrication of bearings in high temperatures such as furnace bearings and mechanisms in contact with oxygen, alkalis, solvents, gas and flammable fuels.

PFPE greases offer the ultimate in lubricant performance with extremely long life and they excel in the most aggressive working conditions.

IKV fluorinated lubricants are branded ZAROX, FLUOR and TRIBOFLON offering the ultimate in choice from a full range of different viscosity base oils, pastes, greases and dispersions with additives where required to suit the specific application.

From equipment selection to maintenance cycles and troubleshooting, we know you work tirelessly to achieve peak plant performance every day. With the average plant using more than 2,000 bearings – in addition to the valves, seals and other PFPE lubricant reliant components – lubrication plays a critical role in plant performance.

Finding a lubricant that can perform, even in the harshest of conditions, can help extend asset life, reduce downtime and control maintenance costs. Perfluoropolyether (PFPE) lubricants are proven to outperform traditional lubricants in four key areas: over time, under extreme pressures, in extreme heat and in extremely harsh conditions.

PFPE lubricants have proven endurance over time at extreme temperatures. In fact, a British bottling plant was struggling to keep its labeling machine gearbox operating fulltime because shaft seals lasted only two weeks. This led to frequent unscheduled downtime and high maintenance costs. The company needed a lubricant that would withstand extremely high temperatures over time, minimize leakage from failing seals – which produced a food quality concern – and was safe for its employees.

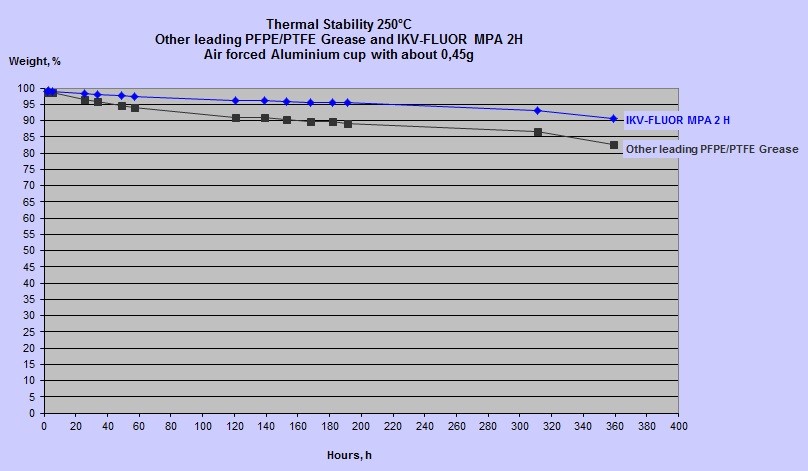

The Test of Heat

Numerous tests have demonstrated PFPEs’ reliable performance under high heat, maintaining lubricity at temperatures greater than 400 °C (752 °F). A notable example comes from the ammonia industry. One company was plagued by frequent bearings failures in its reformer furnace blower due to the lithium grease decomposing at the high operating temperature (290 °C [554 °F]). The company sought out a chemically inert lubricant – capable of performing alongside ammonia – with a once-a-year re-lubrication cycle due to the maintenance safety risk, potential fire hazard involved with shutdown and production loss.

A high-temperature PFPE lubricant, specially designed to provide optimal performance between 200 °C and 300 °C (392 °F and 572 °F), met the challenge. Because PFPEs are nonflammable and chemically inert, safety improved. As a result, the bearings in the reformer furnace blower do not lose lubricity and the maintenance schedule can remain confidently at 12 month intervals, reducing the company’s operating costs and safety risk.

The Test of Harshness

Lastly, PFPE lubricants provide optimal performance in extreme conditions. A Taiwanese manufacturer struggled to adequately lubricate the pressure gauge within its chlorine piping system, part of a titanium dioxide manufacturing operation. Gauge failures threatened worker safety, resulted in downtime and increased maintenance expense.

The company searched for a replacement lube that was stable at high temperatures, resistant to chlorine gas and could handle the harsh operating environment. The company met the challenge by using a nonflammable PFPE lubricant with good high-temperature stability, providing long-term stability at operating temperatures up to 150 °C (302 °F).

Performance over a wide temperature range

Extreme heat or cold have no effect on the lubricity of these lubricants, effective from -75 °C to greater than 400 °C (-103 °F to 752 °F), depending upon operating conditions and product grade.